Introduction

Knowledge of ore and gangue is essential for the geometallurgy development since the prediction of metallurgical performance largely depends on the correct interpretation of these variables.

Regarding the ore characterization, several methods have been proposed with different quality of deliverables and costs (we will address these methods in future installments). We will focus on normative mineralogy estimation methodology using partial digestion chemical methods.

Partial digestion methods date back to the early 1900s, were developed with the goal of identifying the leachable portion of mineralized rock.

Later developments allowed to identify important correlations between tests results with some sulfides and oxides mineralogies, which led to implement the mineralogical ore characterization in the workflow of modeling a mining deposit.

Methodology

Partial extraction methods allow to estimate mineralogy by solving the following equation:

Where A corresponds to the end-members matrix (partial digestions results to pure mineral species), x is unknown, which corresponds to the mineralogy distribution in relation to copper content (in this case), while B corresponds to the partial digestions results matrix using different chemical attacks.

The ore mineralogy estimation process can be summarized in the following diagram:

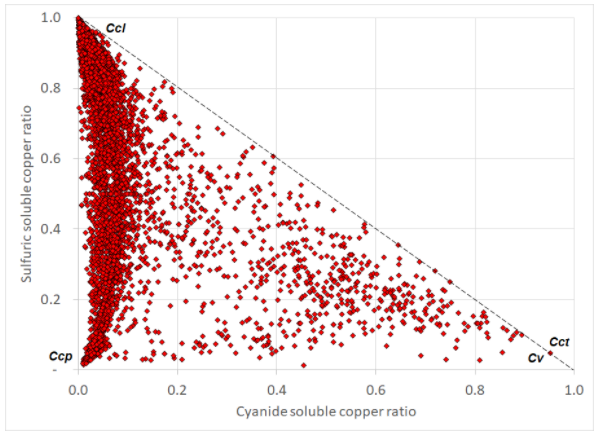

In the figures below, a case developed under this methodology is shown. The position of each end-member defined for the orebody under study is located in black, while each point represents the values obtained by partial digestion using ferric (FSCu) and cyanide (CNCu) solutions in relation to total copper (Cu). The chemical attacks selection is relevant since they allow to differentiate the majority mineralogical species (end-members) in the solubility diagram.

Finally, the mineralogy estimation using partial digestion analytical methods is a process that requires:

- Correct workflow definition.

- Quality control and assurance at each stage.

- Support from a team of geologists with experience in each deposit type.

- The results’ predictive quality must be validated with alternative modal mineralogy methods.