In last week’s publication, Daniele Beck told us that Geometallurgy forms a bridge between the professionals involved in the production chain in mineral deposits … this made me remember when a group of 8 students from Execution and Civil Engineering in Metallurgy chose an elective course called “Plant Design”, it was the 90’s and the penultimate semester of our careers, which involved two great challenges: working as a team and meeting the objective of the course in terms of time and quality.

That is how we formed work groups and each group was given a 100 kg bag of mineral along with the condition of working as a team and delivering a plant design technical report at the end of the semester. We looked at each other and the first questions were: What do we do now? Can we create synergy between the groups? Is there a work program?

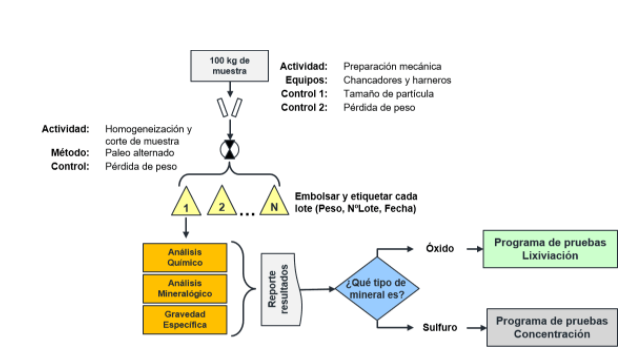

We got down to work and the first thing was to plan a general mineral characterization program and answer the fundamental question: Are they oxides or sulfides? We generated a process diagram like the following one and start working.

At Mine to Port Consulting, we have experience to support you in the planning and development of each of the activities, analyzes and tests, being our job to accompany you to obtain results that are auditable (comply with quality and ISO 9001 standards) and employable in your company’s projects: technology evaluation, changes in process conditions and process plant operation control.